Talk to us

08071932074

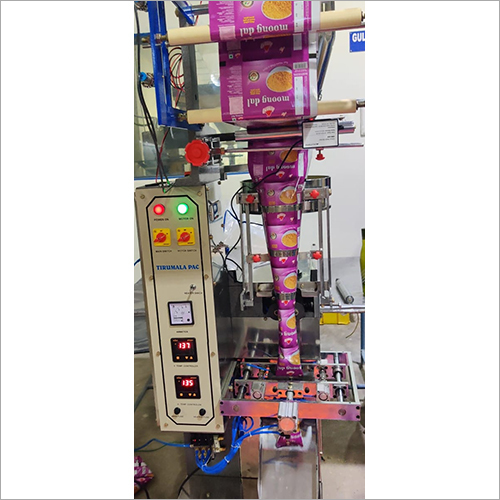

A specialised packaging device created to automatically package half dal (split lentils) or other comparable granular items is known as a pneumatic automatic half dal packaging machine. Pneumatic describes how a machine works by using compressed air or pneumatic parts.

1. Half-dal or split lentils to be packaged are held in the machine's hopper or feeding mechanism, which is a feature. A controlled and reliable supply of the product for packaging is ensured by the hopper.

2. To precisely measure the appropriate quantity of half dal, the packing machine integrates a weighing or metering device. This system makes sure that each package is filled precisely and contributes to maintaining the packaged product's consistency.

3. Forming a Bag or Pouch: A roll of packing material, usually comprised of flexible films, is fed into the machine, which then moulds it into a bag or pouch. To make the bags or pouches, the packaging material is taken from the roll and fed through various stations in the machine.

4. Filling and Sealing: After the pouches or bags are created, the measured amount of half dal is automatically dispensed into each pouch or bag. The machine then seals the bags or pouches to preserve the product's freshness and stop spills. Depending on the packing material, sealing techniques may include heat sealing, impulse sealing, or other suitable processes.

5. Trimming and Cutting: The machine trims the filled bags or pouches from the continuous film after sealing. Trimming mechanisms can be used to cut off extra packing material or to shape bags or pouches into a certain shape.

6. Compressed air or pneumatic components are used for a variety of tasks by pneumatic automatic half dal packing machines. This can involve regulating the motion of machine components, turning on valves, or using cutting and sealing mechanisms.

7. Control and automation: To manage and keep an eye on the packaging process, the packaging machine is outfitted with control panels or programmable logic controllers (PLCs). Operators may change filling quantities, establish parameters, check machine performance, and keep tabs on production data thanks to these controls. Operations for packing are efficient and reliable because to automation features.

Price:

Price 135000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Type : Filling Machine

Computerized : No

Drive Type : Mechanical

Price 380000 INR / Unit

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Type : Vacuum Packing Machines

Computerized : Yes

Drive Type : Hydraulic

Price 130000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Type : Filling Machine

Computerized : Yes

Drive Type : Hydraulic

Price 140000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Type : Embossing Machine

Computerized : No

Drive Type : Hydraulic